In today's globalized economic environment, Chinese-made machinery and equipment are emerging in the international market with their excellent quality and advanced technology. Among them, the high-speed trapezoidal tile roll forming machine, as an indispensable equipment in the construction industry, has been successfully exported to Saudi Arabia with its high efficiency, precision and stable performance, injecting new vitality into the local construction industry.

The features of this high-speed trapezoidal tile roll forming machine:

- Efficient capacity: producing speed can reach 40m per minute

- Transmission: by gearbox

- Precision mold:with high-precision molds and advanced calibration systems

- Stable and reliable performance : made of Hot rolled H-beamand advanced welding technology, the structure is sturdy and durable

- Easy to operate and intelligent :user-friendly operation interface and an intelligent control system, operators can easily get started with simple training

The technical specifications of a high-speed trapezoidal tile roll forming machine:

1.10 tons hydraulic Uncoiler:

- Capacity:10 tons

- Coil width: max 1250mm, as customer’s request

- Working type:passive type with brake to stop the uncoiler; hydraulic coil core expansion

- 4 support arms design: support the coil and prevent crease when uncoiling

- Make sure a high-speed feeding of the material

- The car can move levelly and vertically, which is convenient for putting the steel coils into the uncoiler.

10 tons hydraulic decoiler

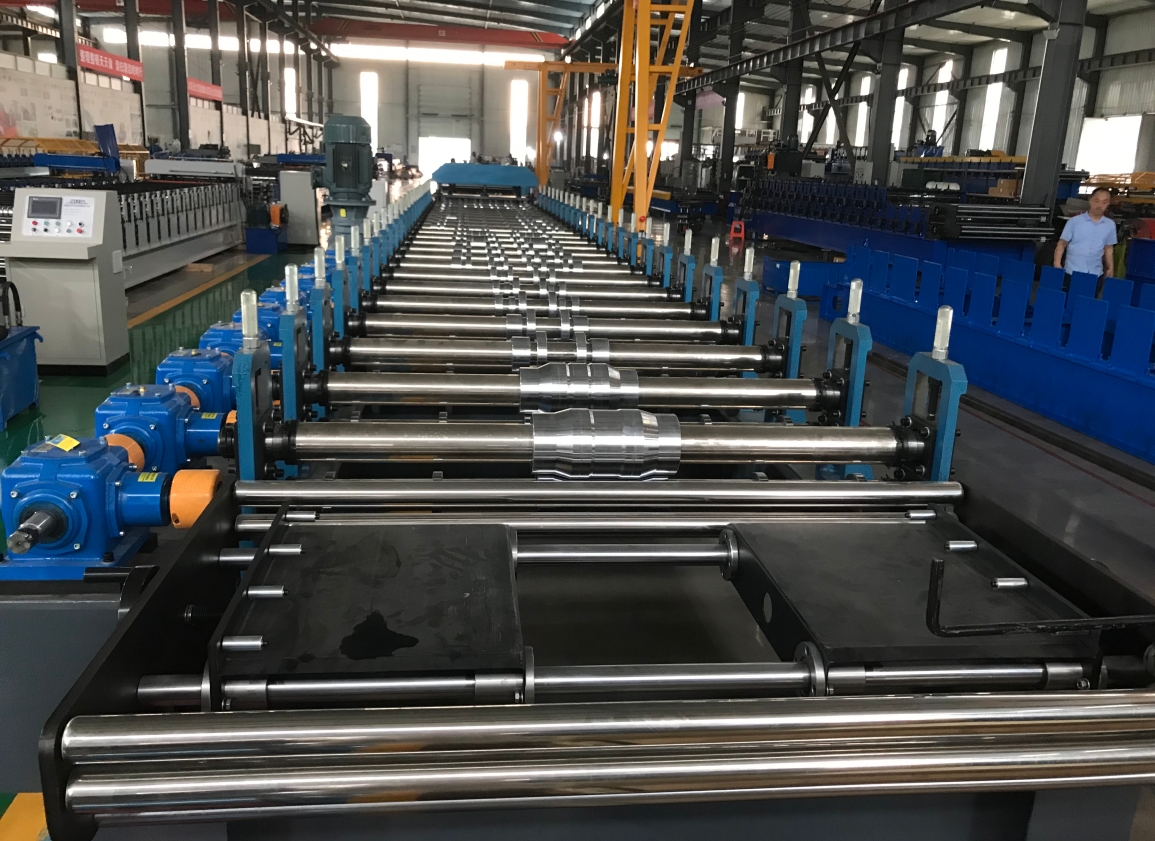

2.Roll forming machine:

- Arch frame with 40 mm thickness;connected with the body by bolts and nuts

- Roller Station: 23 stations

- Roller material: 45#,finishing after quenching heat treatment, to ensure that high rotation does not produce heat, to ensure hardness and urgent service life

- Roller shaft: 45# material Tempering treatment, prevent deformed and improve the hardness; diameter:80 mm

- Transmission type:by gearbox

- Speed:0-40m/min

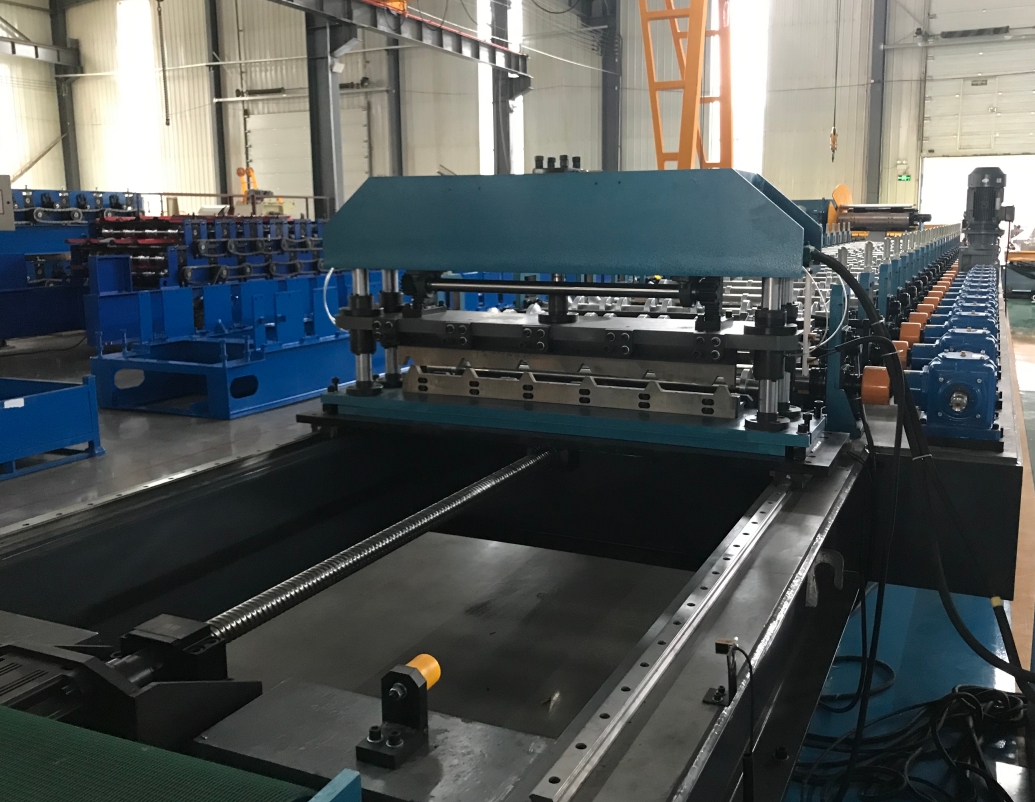

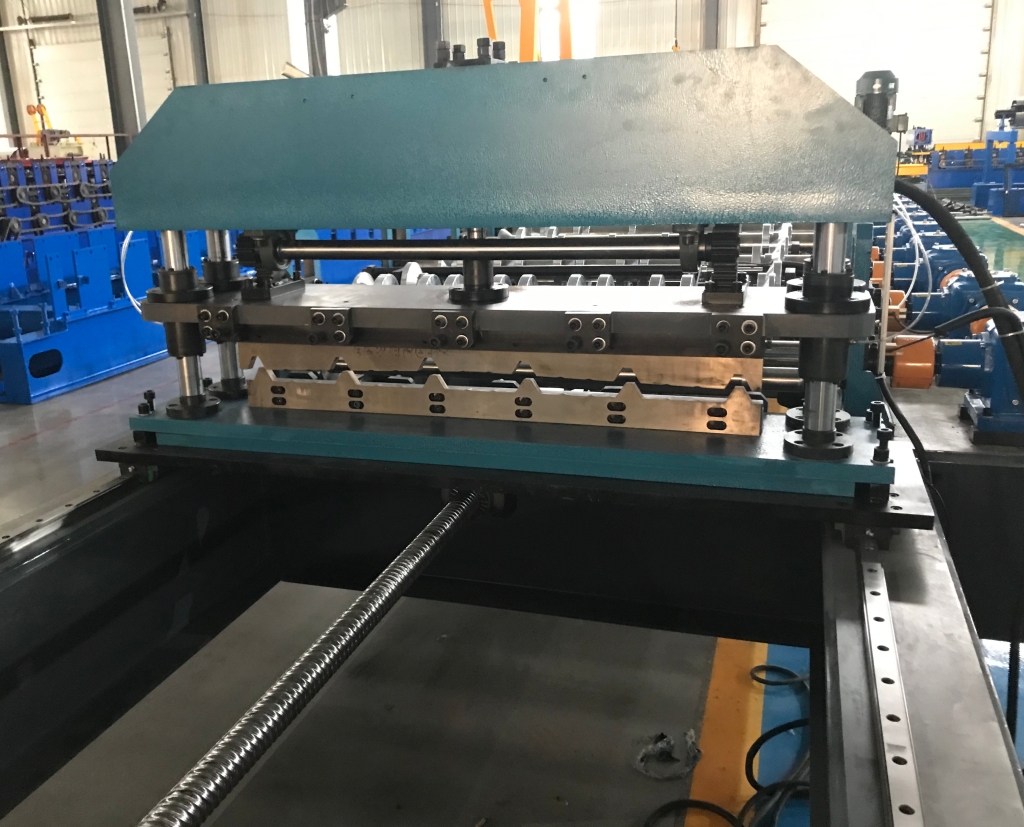

3.Hydraulicservo cutting system

- Automatic hydraulic cutting controlled by PLC

- no-stop cutting design: moving by the servo motor

- Material of cutting blade:GCr12Mov

- Steady and safe working condition and low sounds

4.Automatic stacker:

- allows free unloading of each cut profile and automatic placement on the stack of previously made products

- the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet

- save much more space and cheaper than full automatic machine

- Stacker dimension:6500 mm×2100 mm×1600 mm(the length can be customized as your requirement)

No Comment

You can post first response comment.