The trapezoidal roof sheet roll forming machine is an advanced equipment specially used to produce trapezoidal roof panels.

The trapezoidal roof sheet roll forming machine is an advanced equipment specially used to produce trapezoidal roof panels.

This roll forming machine uses advanced molding technology, has high strength, good stability, and can withstand large loads and pressures.

From an economic point of view, the trapezoidal roof sheet roll forming machine can reduce production costs. Through automated production, labor costs are reduced, while the utilization rate of raw materials is improved and waste is reduced.

The features of this trapezoidal roof sheet forming machine:

- Efficient capacity: producing speed can reach 25m per minute

- Transmission: by double chain with cover box

- Accuracy and quality are guaranteed:The size and shape of the roof panels can be highly uniform

- Wide material adaptability : GI, GL,PPGI, PPGL

- Flexible :According to the requirements of the architectural design,the length can be adjusted according to actual needs, and the thickness range of the material is 0.3mm-0.8mm

The technical specifications of a trapezoidal roof sheet roll forming machine:

1. Roll forming machine:

- Machine frame: 350 mm H beam structure, with 20 mm thickness welded steel middle plate

- Roller Station: 17 stations

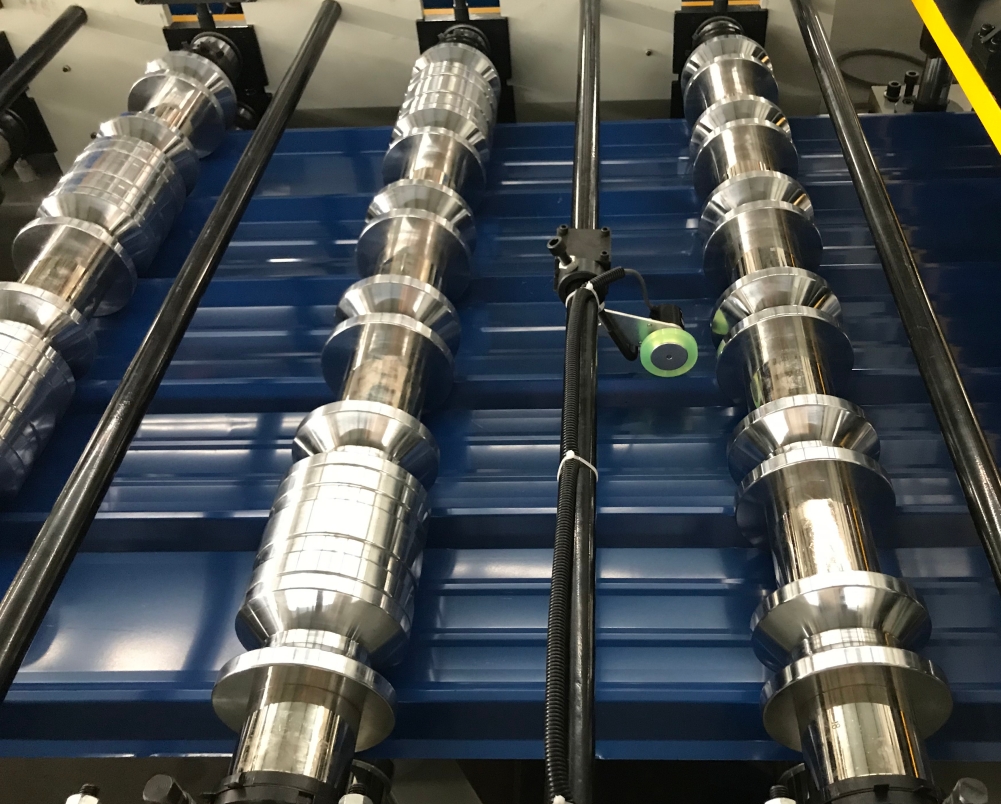

- Roller material: 45#,finishing after quenching heat treatment, to ensure that high rotation does not produce heat, to ensure hardness and urgent service life

- Roller shaft: 45# material Tempering treatment, prevent deformed and improve the hardness; diameter:80 mm

- Transmission type:by double chain with cover box

- Speed:0-25 m/min

2. Roll forming machine:Hydrauliccutting system

- Automatic hydraulic cutting controlled by PLC

- Driving method: By double pillar type Cylinder

- Material of cutting blade:GCr12Mov

- Steady and safe working condition and low sounds

3.PLC control station:

- PLC brand:Delta PLC, and transducer and touched screen

- Encoder brand:Omron

- Electrical components:Schneider

- Operating language:English and Chinese(or as requested)

- You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

No Comment

You can post first response comment.