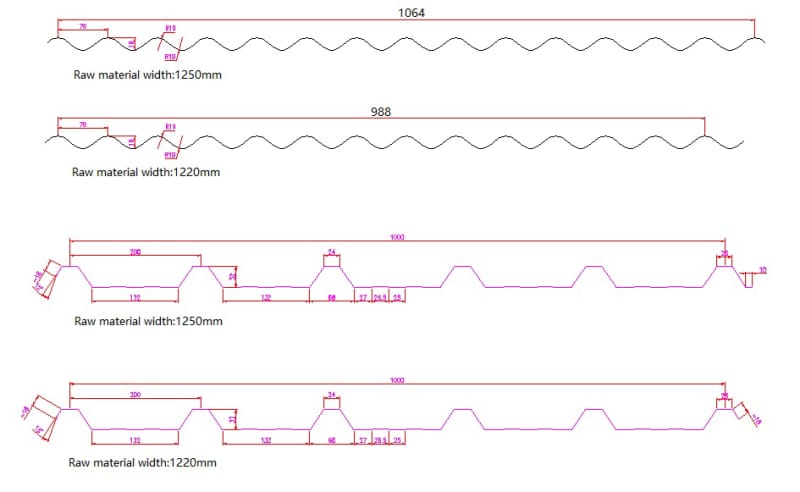

Roofing Sheet with Felt Roll Forming Machine for Ireland Market

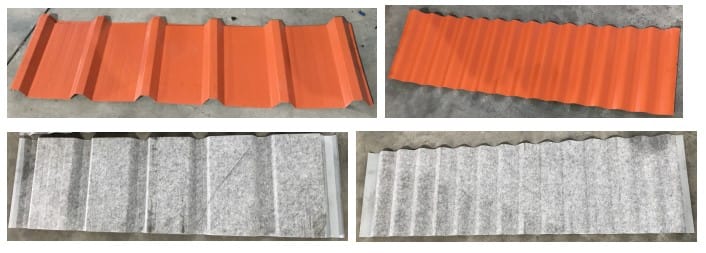

This is a standard profile which is used in Ireland,the feature of this machine is to add the felt device which can attach the felt on the bottom of the sheet.

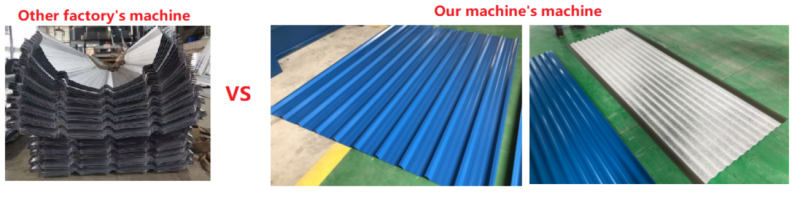

The common problem of the most machine manufacturer: Because this sheet need to add the felt on the bottom of the sheet,so it increase the difficulty of the machine’s design.A lot of factories’ machine can’t produce the flat sheet,it has a big curve of the sheet.But our machine can make the sheet very flat,please see the comparison in the delow:

The technical specifications for the Roofing Sheet with Felt Roll Forming Machine for Ireland Market:

| Name | Specifications | |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.6mm(thickness range shouldn’t be too big) |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Felt device | Available |

| 5 | Roller station | 17+19 stations |

| 6 | Roller material | 45# steel with quenched treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel with tempered |

| 9 | Transmission | by chain |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel welded |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

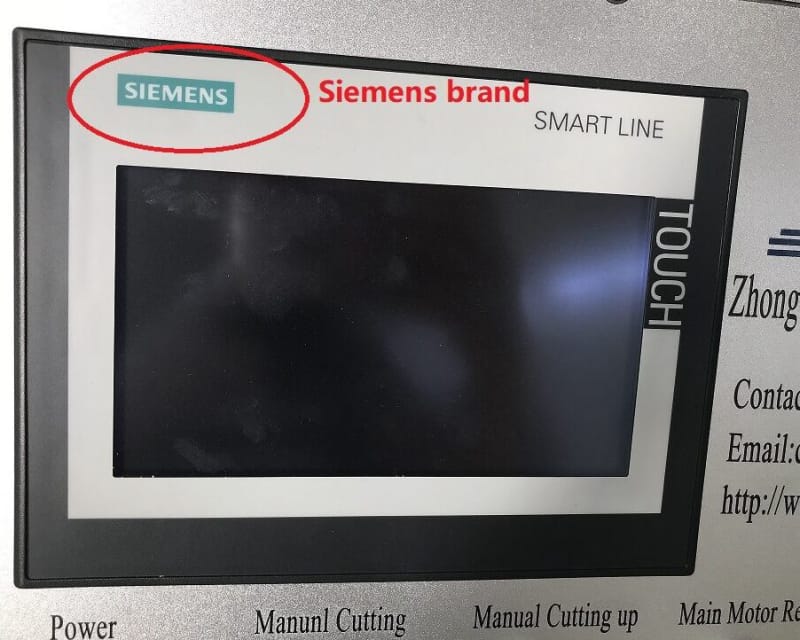

| 17 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

The Components of each part and Introduction:

Part 1:Decoiler

The capacity of decoiler:For normal coils which is used in roofing sheet,the 5 tons capacity is enough.

If customers have special request about the capacity,we also support customization as customer’s request.

For the decoiler,we have two types,one is manual and another one is automatic.

The difference between manual and hydraulic decoiler in the below:

| Manual decoiler | Hydraulic decoiler | |

| 1. | No power,it is drived by the roll forming machine | Has power,it can work automatically |

| 2. | Need to adjust the decoiler shaft manually according to coil inner diameter | Automatically adjust the decoiler to fit into the coil according to the coil diameter |

| 3. | With simple brake and handwheel for easy working | With Pneumatic braking system With press arm to keep coil from loosing With speed sensor to match with whole line’s speed |

| 4. | Price is cheap | Price is a little higher than manual one |

Manual decoiler Hydraulic decoiler

Part 2: Felt device

Part 3:The main roll forming machine

(1) For the feeding part, we use the roller design to protect the surface of the coil.

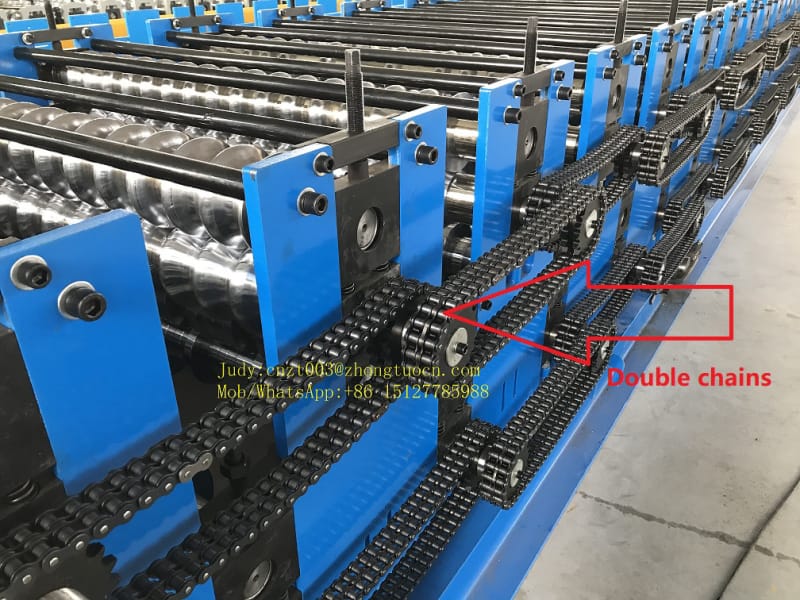

(2) For the transmission, we use the double chain.

(3) For the base frame, we use the strong with more supporting to make sure the machine working more steady.

(4) For the main motor we use Siemens, if you need we can customize according to your needs.

(5) For the shearing part, we use two pillar supporting shearing to make sure the shearing more accuracy and long time to use.

(6) For the rollers are with the key note and good chroming to make sure long time to use.

(7) We add the clutch in the double layer machine,which can reduce the abrason of the rollers.

Part 4:Control system

(1) We use world famous brand:

Touch screen:Delta,Siemens,Mitsubishi

PLC:Delta,Siemens,Mitsubishi

Low voltage apparatus:Schneider

Encoder:Omron

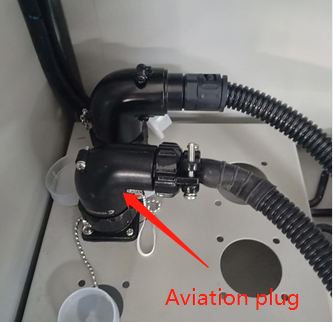

(2) Use aviation plug for customer to easy connection power

Part 4:Hydraulic system

Brand:Beijing Huade,Chinese famous brand

Magnetic valve:Big valve for good working

Cooling system:Fan cooling.

Part 5: Auto stacker

No Comment

You can post first response comment.