描述

Steel Sheet Slitting Line Machine for Metal Simple Automatic Supplier Manufacture Stainless Steel Coil Slitting Line

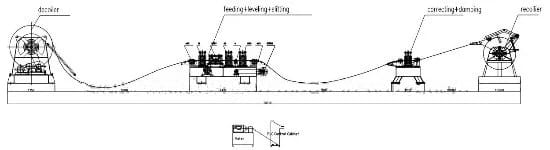

Steel Sheet Slitting Line Machine for Metal Simple Automatic Supplier Manufacture Stainless Steel Coil Slitting Line is one most popular type of metal plate slitting lines. It consists of Decoiler, Feeding system, Leveling System, Slitting System, Scrape coil system, Correcting&Damping system, Recoiler and Electrical system. It's suitable for processing thickness range from 0.2mm to 2.0mm thick, metal sheet width from 300-1250mm steel coils. This slitting line can run with max work speed 30m/min. We adopt 18mm wall board to make machine frame strong, moreover, PLC with touch screen operation make the line simple and easy to usage.

Working flow:

Decoiler-Feeding---Leveling---Slitting----Correcting and Damping-Recoiler

Components of equipment:

| Motor decoiler | 1 set |

| Slitting | 1 set |

| Correcting and damping | 1 set |

| Auto hydraulic recoiler | 1 set |

| Electrical control cabinet | 1 set |

Detailed information:

| 1) Motor decoiler | |

| Motor: | 5.5kw |

| Capacity (Max): | 8 Tons |

| Inner diameter | 450-550mm |

| Coil Width (Max.): | 1250mm |

| 2) Coil transmission | |

| Transport roller: | 45# forge steel, quenched and chrome coated 0.05mm |

| Width of roller: | 1500mm |

| Motor power: | 3KW |

| 3) slitting part | |

| Disc slitting blade | |

| Number of disc blade: | 11groups |

| Material of disc blade: | Cr12mov |

| Material of main shaft: | steel and Rubber covered |

| Slitting speed: | 20-30m/min |

| Motor power: | 11KW |

| Scrape recoiler | |

| Rotary according to slitting device | |

| 4) correcting and damping | |

| Correcting rollers: | three rollers, 45#forge steel and chrome coated 0.05mm |

| 5) Recoil system with correcting device | |

| Expanding: | hydraulic |

| Capacity: | 5 Tons |

| Hydraulic power: | 5.5KW |

| Motor power: | 7.5KW |

| Inner diameter | 450-550mm |

| Recoiler width | 50-1250mm(adjustable) |

| Automatic recoil with correcting device | |

| 6) Electrical control cabinet | |

| Electrical system: | PLC Panasonic 380V, 50HZ, 3 phase(also depend on customer demand) |

| Transducer | YASKAWA, made in Japan |

| Weight | 10.5 tons |

| Production area | 18.5x3.5x2.1meters |

Character of main structure:

The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

It is very easy to install the equipment and suitable for producing in the factory.

Low noise with high efficiency.