Description

New design of lace shearing and molding cutting glazed tile rolling forming machine

New design of lace shearing and molding cutting glazed tile rolling forming machine is designed to make the step tile or glazed tile in batch fully automatically. It can reach the speed of 7 to 11 meter per minute:

Features of lace shearing and molding cutting glazed tile rolling forming machine:

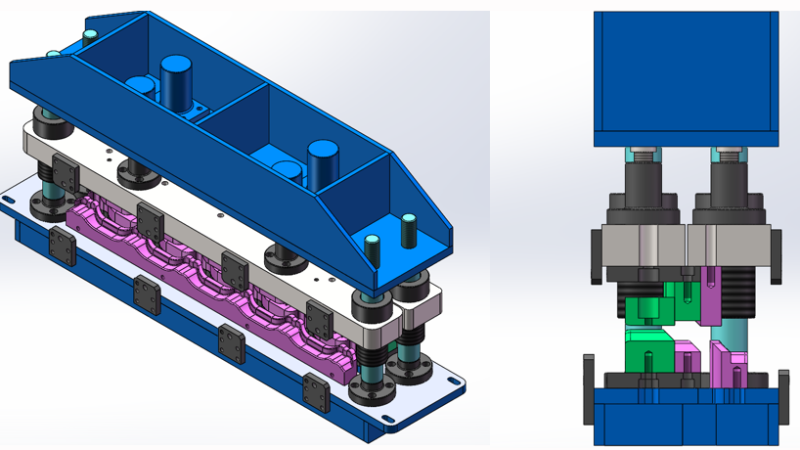

- It includes a cutter holder, the upper part of the cutter holder with an oil cylinder,

- With an upper knife beam, upper cutting knife is fixedly installed on the upper knife beam through the connecting plate, and the lower cutting knife is arranged corresponding to upper cutting knife.

- The lower cutting knife is fixedly installed on the lower knife beam, and the lower knife beam is arranged on the cutting knife frame.

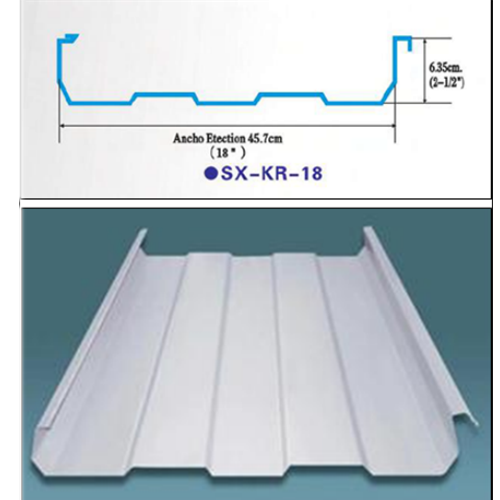

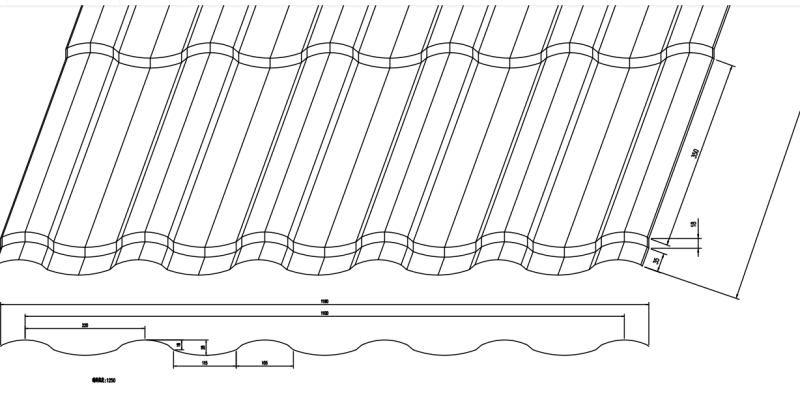

Take the following drawing profile to show you the lace cutting and molding shearing:

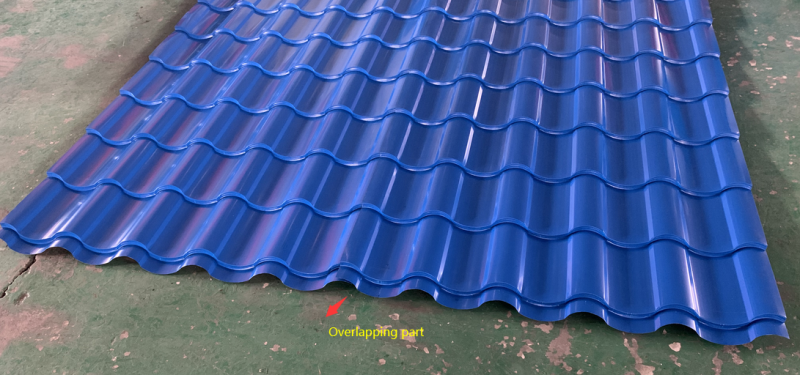

Finished product pictures:

More detail design of the shearing and stepping part:

Here are some machine parameter for your reference:

| Suitable material | PPGI coils & Aluminium coils ;0.4-0.5mm |

| Working speed | About 6m/min |

| Step distance | Adjustable according to requirement (>=250mm) |

| Power Requirement | Main motor power: 5.5 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Dia. is 72mm.Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 10500KGS |

| Machine's size | About 18m x 1.8m x 1.5m (Depend on final design) |

Here glazed tile rolling forming machine pictures for your reference:

Now let us know more about this machine by the following video: