Description

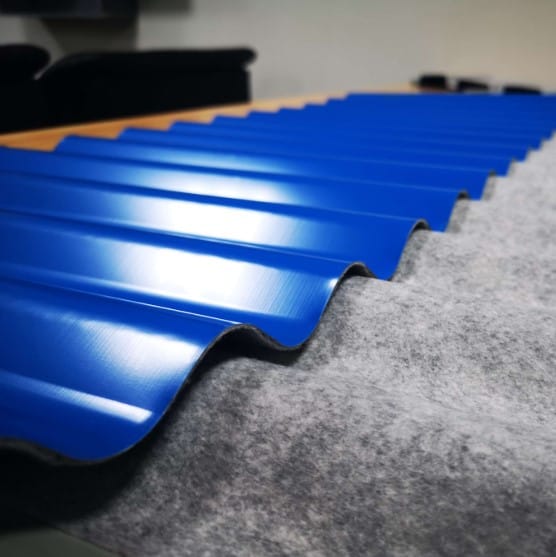

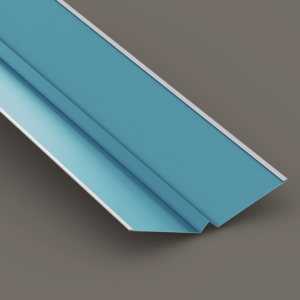

PE/Nanomembrane/PVCPET filming hot metal filming production line is designed to use of plastic film (PET, PVC, PVDF, ASA) through the hot melt and metal plate to solve the corrosive problem of metal plates and metal containers. The finished products of PET, PVC, PVCF, ASA felt PPGI is not only has the decorative and diaphragm properties of plastic films, but also has the plasticity and flexibility of metal plates, formality.

Metal plate: galvanized plate, stainless steel plate, cold rolled plate, aluminum plate.

Plastic film: PET, PVC, PVCF, ASA, etc.

Film color: color/color; wood grain, marble grain, brick grain, stone grain, pattern, brush, relief.

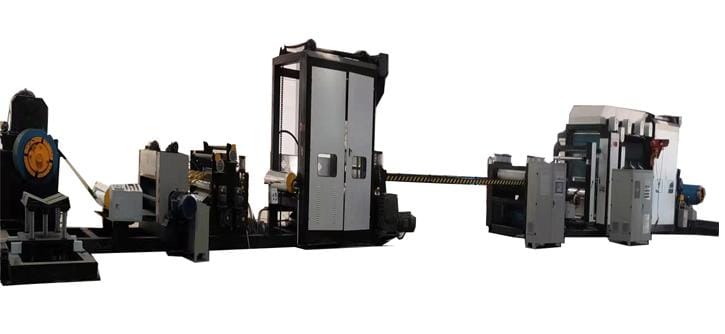

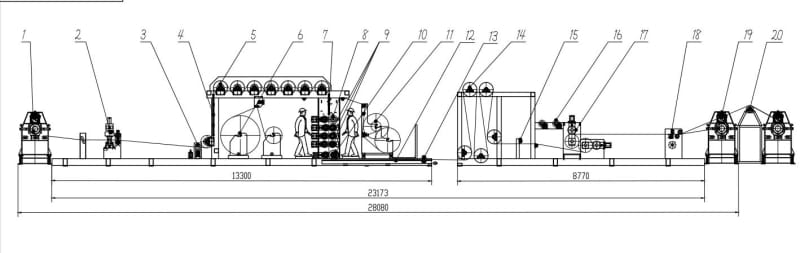

PE/Nanomembrane/PVCPET filming hot metal filming production line working flow:

PE/Nanomembrane/PVCPET filming hot metal filming production line is composed by the following elements:

- 10 tonsDecoiler machine; hydraulic automatic side alignment, equipped with hydraulic trolley, unwinding motor 22KW 6-pole, direct-connected gear box,

Motor brand: Xijiang

Encoder: Kübler, Germany.

- Plug-in belt splicing machine, hydraulic control, the thickness of the splicing plate is less than 0.5mm; hydraulic solenoid valve Taiwan oilshun, with small rolling car flattening.

- Cylinder brake coil changing and rolling car

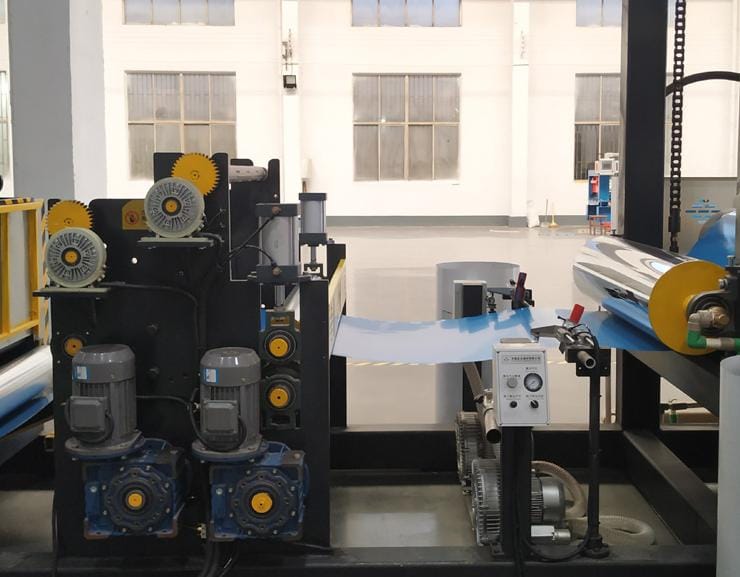

- Heating system: A heating roller with a diameter of 500mm, with automatic temperature control. Peripheral perforation is used, and the built-in graphene 0-200 ° takes only minutes, and the heat transfer efficiency is high. A total of seven groups.

5.Bottom guiding and laminating device:Bottom laminating and unwinding process, with double-station unwinding and automatic constant stretching, with correction function. Magnetic powder 20KG.

6.Auto-heating system:Super audio heating, infrared probe, automatic temperature control.

7.Compound heating rollerwith a diameter of 350mm, electric heating tube auxiliary heating, automatic temperature control

8.Optional embossing rollers: Group embossing rollers, patterns can be matched by themselves, cylinder diameter 160mm, electric heating tube auxiliary heating, automatic temperature control.

9.Corner roller,diameter 350mm, 2 times compound.

10.Overlay film unwinding process, with double-station film unwinding, automatic constant tension, with correction function.

11.Cooling station1, equipped with 4M water tank.

12.Water roller

13.Cooling station2, equipped with 8 sets of 500mm diameter cold water rollers, good cooling effect.

14.Trimming device: The trimming device automatically tracks the edge and automatically sucks away the edge material.

15.Protective film on double station;

16.S-roller tractionof the main machine, the diameter of the rubber roller of the main machine is 500mm, the cylinder is 200mm in diameter, the gear box is 250 type, and the motor is 4 stages 18.5KW

17.Shearing machine: The shearing machine, the cutter motor is 2.2KW, which is convenient for cutting.

18.Double rewinding machine, cantilever load-bearing 10 tons, hydraulic automatic aligning, with hydraulic trolley, rewinding motor 8 pole 37KW. Direct gear box, motorXijiang Ge Shi, encoder: Kübler, Germany.

19.Convey rollers.

20.Machine size: 28x3x3.5meters,total power350KW