Description

Roof Panel Roll Forming Machine For ZT22-1070 Profile

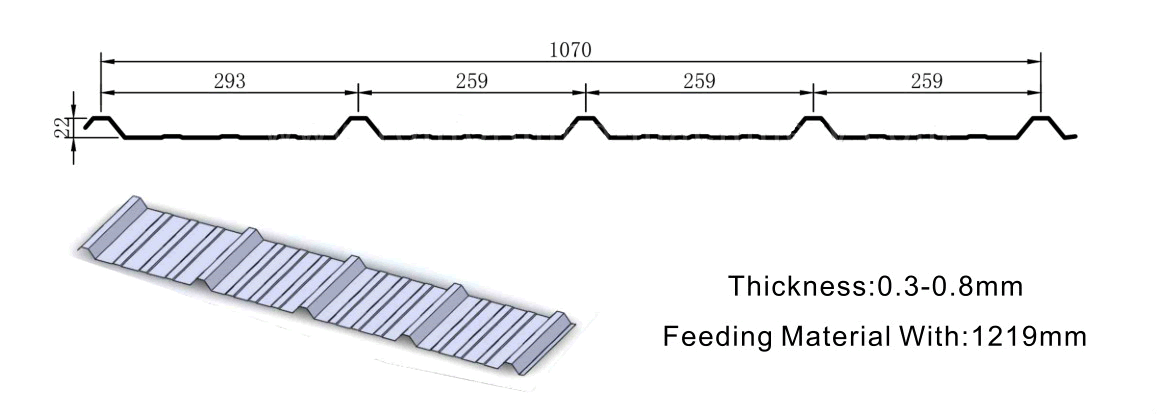

ZT22-1070 Profile Roof Panel Roll Forming Machine is designed for making the metal roof panel sheet production in batch fully automatically. Metal profile ZT22-1070 is designed as:

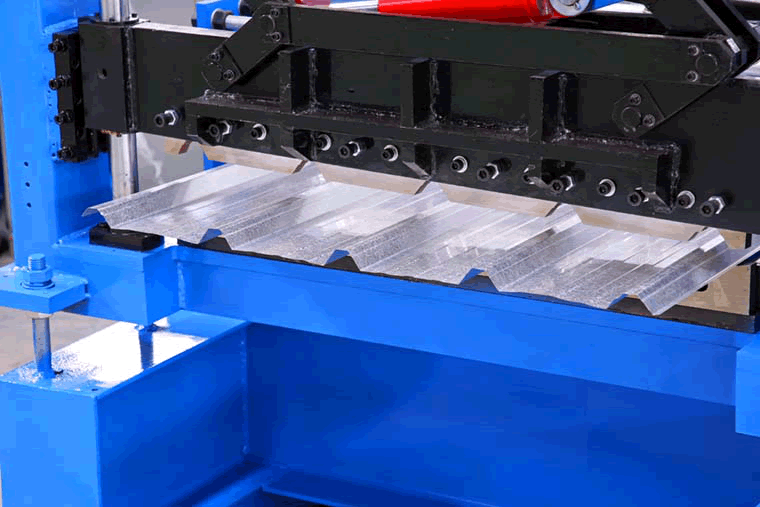

The wave height is 22mm, the wave distance is 259 and the effective width is 1070 and we use the input coil width is 1219mm. And this metal profile is popular in Europe, and other counties.

ZT22-1070 Profile Roof Panel drawing profile for your reference:

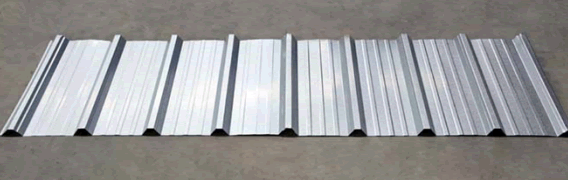

Finished product profile:

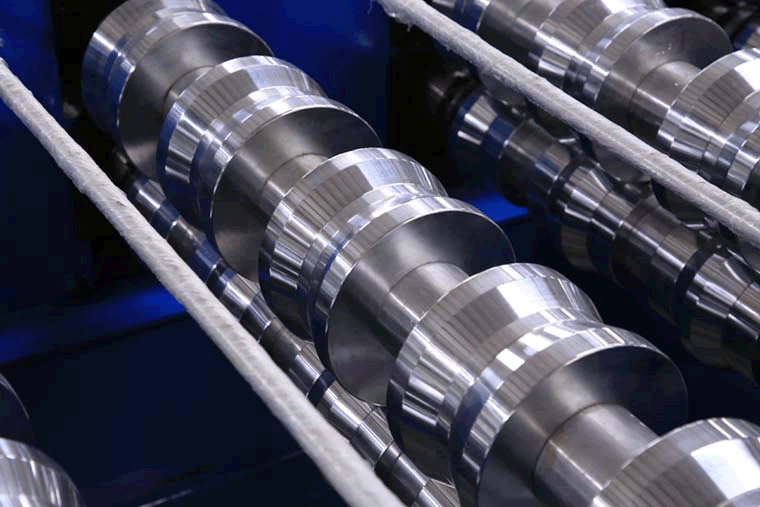

ZT25-205-1025 Profile Roof Panel Roll Forming Machine is Suitable for processing material thickness 0.3-0.8mm. And the shafts manufactured from 45# ,Main shaft diameter75mm, precision machined. And as to the power motor driving,Gear chain transmission,18 steps to form.Main motor=5. 5KW,Frequency speed control. Forming speed approx. 12-1 5m/min

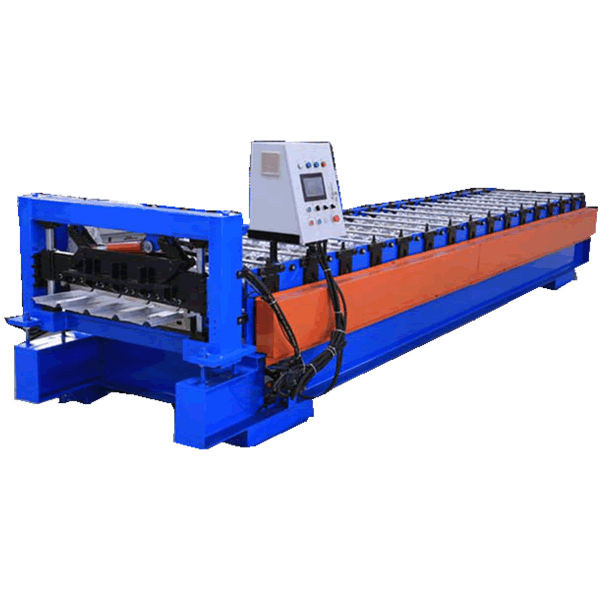

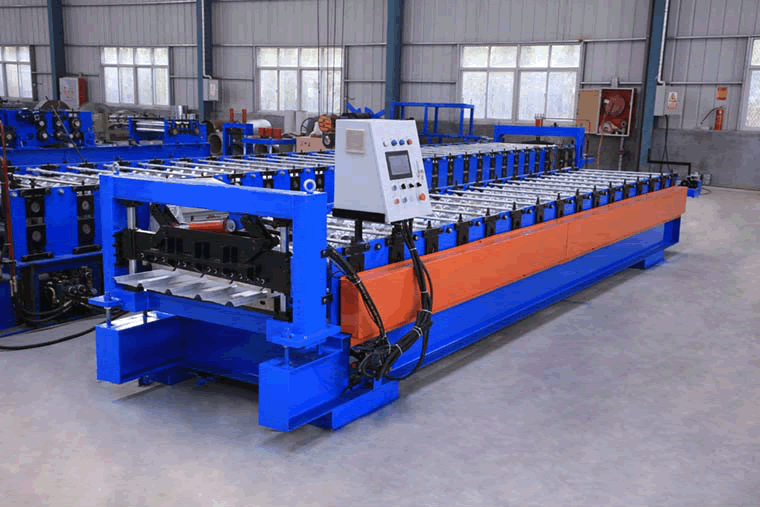

Based on the customer requirements and our experience, we design the ZT25-205-1025 Profile Roof Panel Roll Forming Machine like following picture:

The ZT22-1070 Profile Roof Panel Roll Forming Machine is composed by the following elements:

- Roof panel machine pre-cutter

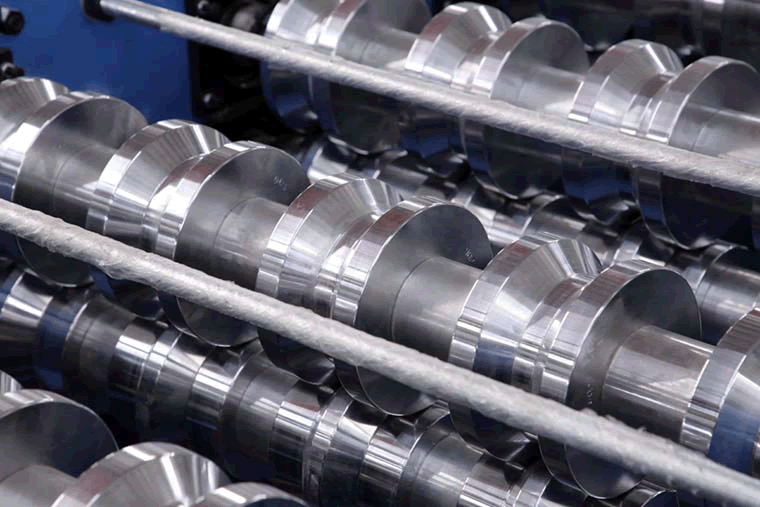

- ZT22-1070 Profile Roof Panel Roll Forming Machine rolling rollers

ZT roof panel rollers we use high quality 45# steel,CNC lathes, Heat Treatment for long time use

And we do black treatment or Hard-Chrome Coating for options.

Machine frame use 350# H type steel by welding

- Shearing part of ZT22-1070 Profile Roof Panel Roll Forming Machine

It takes high quality mold steel Cr12 with heat treatment and the frame made from high quality 20mm steel plate by welding. The power we design Hydraulic motor:4KW, Hydraulic pressure range: 0-16Mpa

- PLC operation system:

roof panel machine touching screen and control panel(Button brand :Schneider / screen brand Schneider)