Description

Strongest Screw-down trapezoidal roofing sheet rolling forming machine is designed to make the Screw-down trapezoidal roofing sheets in batch fully automatically.

Advantages of Strongest Screw-down trapezoidal roofing sheet:

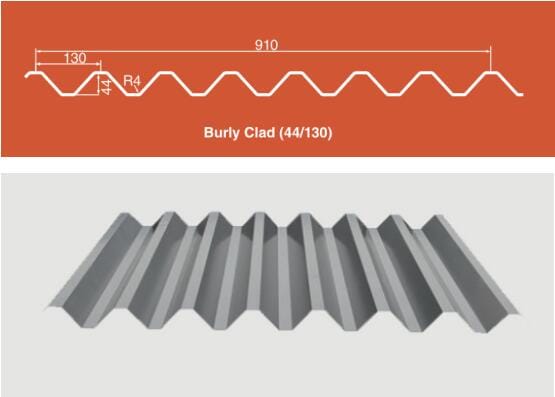

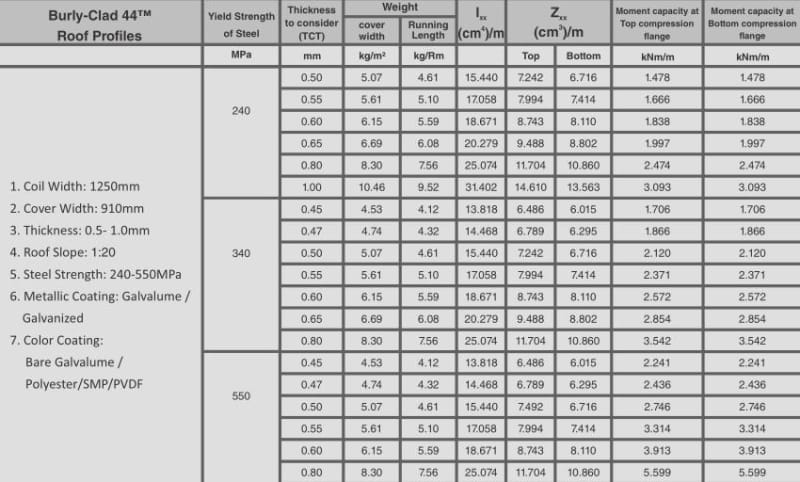

- Strongest Screw-down trapezoidal roofing sheet is available in wide range of aestheticallypleasing colors along with matching corner flashing,capping, gutter etc. to suit your need. As its name shows , this profile is a lightweight & very strong trapezoidal shaped roofing and walling profile designed to take longer span in horizontal and vertical applications.

- This profile is strong as its wave height is 44mm rib and 130mm pitch designed to take static as well as dynamic loads.

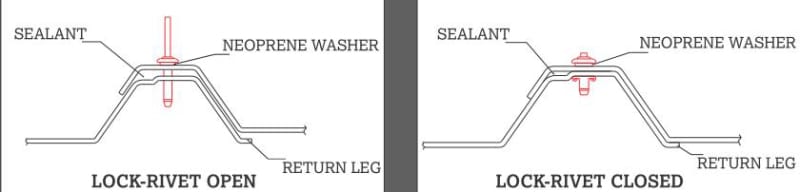

- The full side-lap corrugation gives extra support at the paneloverlap for workability during erection and a better fit for weather tightness.

4.Specially designed side lap anti-capillary groves, which can also be sealed using butyl based sealant tapes to give complete weather tightness from water and dust to make it most suitable roofing & walling system for environment sensitive application e.g. electronic industry, pharmaceutical industry etc.

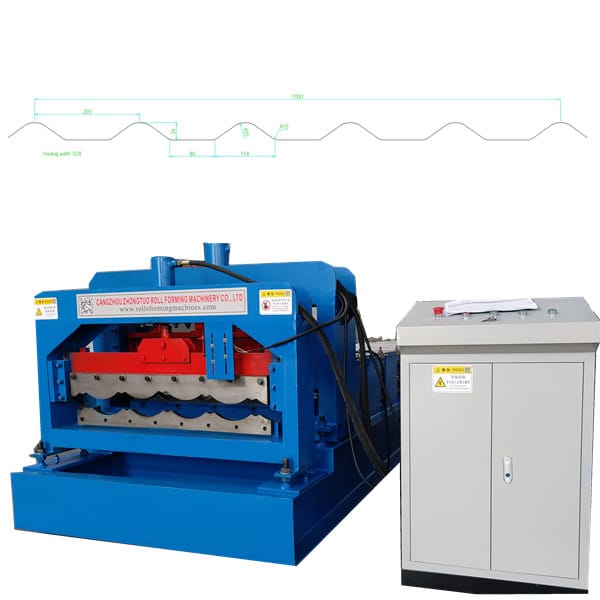

Based on the features of Strongest Screw-down trapezoidal roofing sheet, we design the rolling forming machine like this:

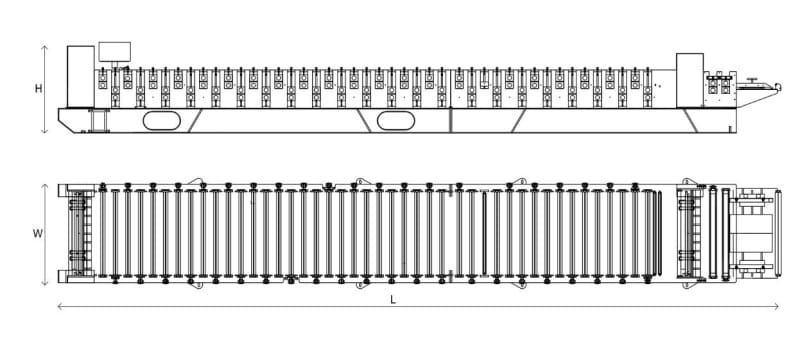

Machine layout for your reference:

Strongest Screw-down trapezoidal roofing sheet rolling forming machine

Machine specification

Rolling speed“12-14 m/min (EECO) 18-20 m/min (Eco, standard)”

Electric power: 3.7 kW-11 kW

Machine Weight: 7.0-13.0 tons

Dimensions (L x W x H)9.0 m x 1.8 m x 1.5 m

Station Quantity: 18-24 stations

Steel Thickness: 0.2-0.8 mm (BMT), MaterialGI, GL, PPGI, PPGL

Coil Width: 914-1450 mm

Material Strength: G300-G550

Production specification

Control System: PLC, Touch Screen HMI

Transmission System Hydraulic, or Gear motor driven by Inverter

Cutting and Pressing System

And for this machine, if you want to know more information, please contact us at any time.