Description

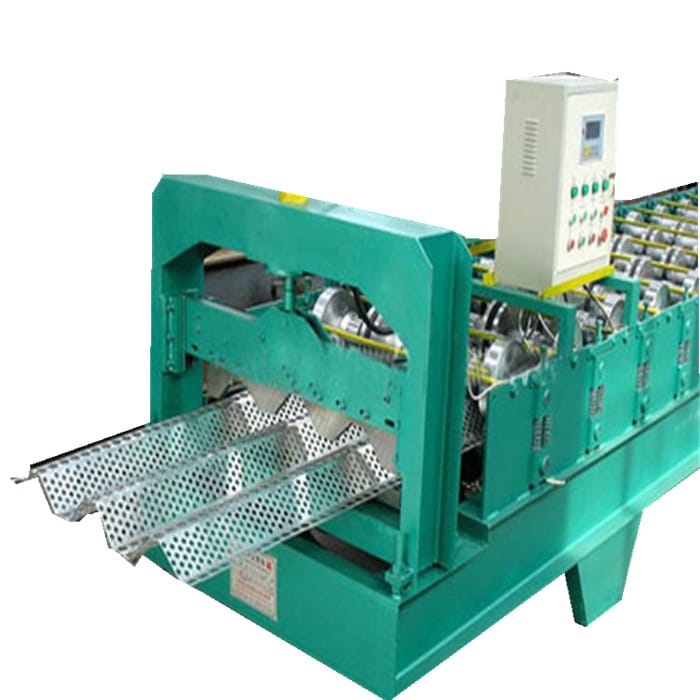

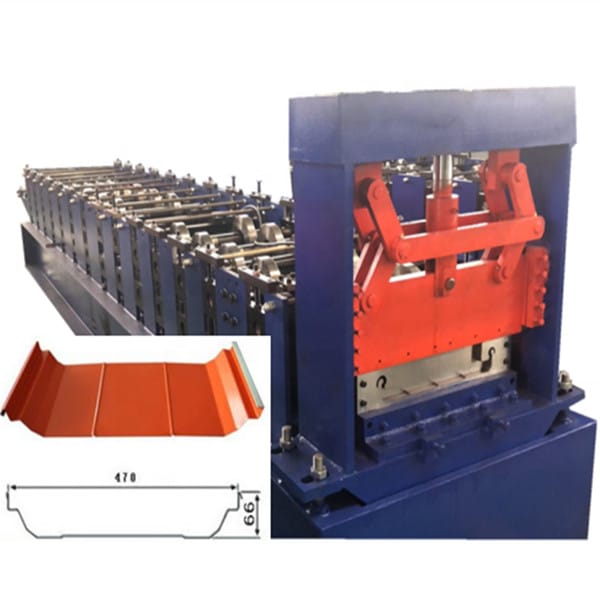

Windshield and Dustproof Board Rolling Machine

Windshield and dustproof board rolling machine is designed to make the windshield and dustproof board in batch fully automatically. The main components of the dust suppression plate produced by the fully automatic pressing and punching production line are based on the principle of aerodynamics, and the structural parameters are designed according to the results of the wind tunnel experiment that simulates the implementation of the on-site environment, and processed into a certain geometric shape. It is corrugated, with round, oblong, elliptical and other openings, which are used to reduce the wind speed of the incoming wind, limit the loss of the kinetic energy of the incoming wind, reduce the turbulence of the wind, and achieve the purpose of windproof and dust suppression.

According to the meteorological conditions of the coal field, the distribution of coal particle diameters, and the geometric parameters of the coal field, the wind and dust suppression board is calculated through experiments and optimized calculations to obtain the mechanical properties, geometric shape, and set of the corrosion resistance and insulation properties that the wind and dust suppression board must meet. , Anti-aging, color and other aspects require computer ingredients. SMC wind-proof and dust-suppressing board is made by compound process.

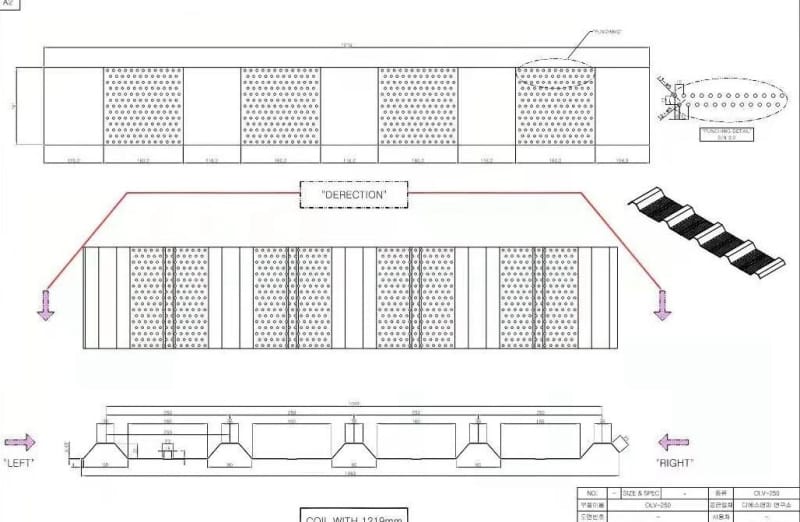

Take the following drawing profile for your reference:

This machine is mainly composed by the following elements: Decoiler, servo coil feeder, punching machine, main rolling forming machine and receiving table.

Here are some machine parameters for your reference:

- Host volume: 7.8 meters long, 1.3 meters wide, 1.2 meters high

- Weight: about 5-5.5 tons

- Main motor power: 5.5KW

- Reducer: planetary cycloid reducer 6# reducer

- The thickness of the middle plate: 16MM

- Sprocket chain: 1.2 inches

- Spindle: Material 45#, shaft diameter?75

- Roll die: 45# steel forging processing, CNC finishing, heat treatment, quenching hardness up to 52°54°, polished and hard chrome plated

- Number of roll rows: 13 rows

- Rollable plate thickness: 0.61MM

- Rolling material speed: frequency conversion speed adjustment is about 1.5 to 3 m/min

- Hydraulic shearing cylinder: double-cylinder drive, cylinder diameter 100MM, stroke 150MM

- Shearing oil pump motor: 4KW

- Shearing tool: Cr12 quenching hardness 6062°, fine grinding wire cutting

- Electrical appliances: Mitsubishi PLC, 7.5

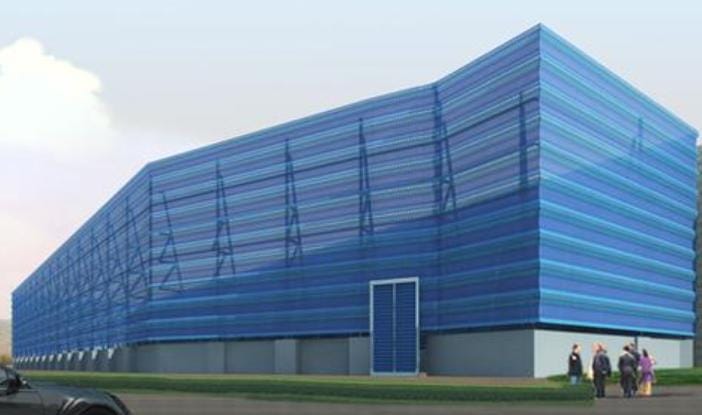

Advantages of wind-proof and dust-suppressing net products:

Because coal yard contains certain sulfur and volatile components, it is an acidic environment with strong corrosiveness. The use of glass fiber reinforced plastic windshield has the disadvantage of being easily corroded by inorganic acids, so it is not suitable for use in acidic environments such as coal yards. Areas with medium and high UV intensity will accelerate its aging process. However, the steel wind-proof and dust-suppression net windshield, only the punched fracture is easy to corrode, in order to prevent the fracture generated after the punching of the windshield from being corroded by the industrial atmosphere of the coal yard, the wind-proof and dust-suppression wall is sprayed with electrostatic powder , The coating film is smooth, plump, water-resistant, abrasion-resistant, oil-resistant, and insulating, and the appearance is beautiful and beautiful. The comprehensive dust suppression rate can reach above 80. Can be made into various colors according to the needs of enterprises.

Here is the machine working video for your reference: