Description

Standing seam roofing system rolling forming machine ZAP 167

ZAP 167 standing seam roofing system rolling forming machine Japanese Technology is designed to make the standing seam in batch fully automatically.

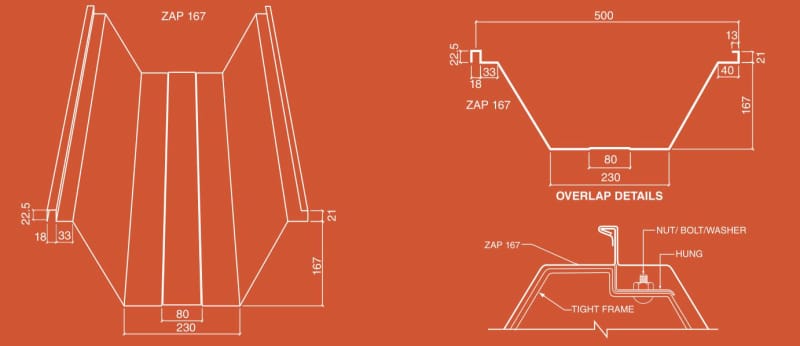

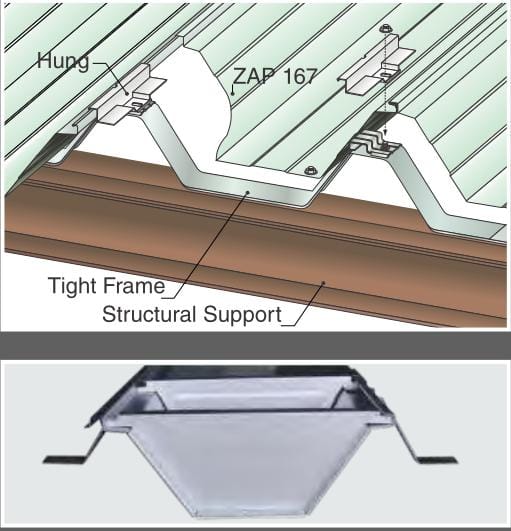

Customer drawing profile for your reference:

ZAP-167 roofing system is a proven and most sturdy Japanese technology. It is a screw less standing seam profile which is 167mm deep, supported on tight frames and can be formed up to single length of 100mts. Available in Galvalume and color coated steel in various colors.Aesthetical and robust looking.80000 sqm installed for prestigious projects like Maruti Suzuki, Bridge Stone etc.

Advantages & Features of Standing seam roofing system rolling forming machine ZAP 167

- The profile has been tested and proven Japanese technology.The machine is good to make such profiles.

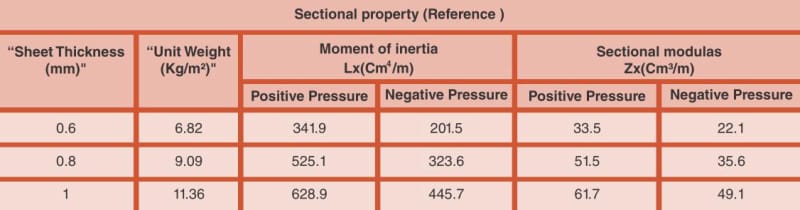

- Robust Design: Depth of 167mm and supported ongalvanized steel tight frames makes it most sturdy roof system to date. It can span up to 4mts. making roof structure more economical and lighter.

- Fitted on tight frame system has high stability againstwind velocity and uplift pressure which is fixed on Purlin.

- Watertight: An exactitude engineered roofing system. Aunique, special designed screw less roof with no end jointsand side laps are seam locked, making it a total leak proof roof.

- High water shedding ability enabling virtually flat roof aslow as 1° Slope.

- Handsome appearance and excellent anti-corrosionperformance.

- Outstanding durability and is suitable for extreme weatherconditions.

- Maintenance free.

- Will last virtually lifetime.

- Matching light panels of FRP / Polycarbonate available.

- 11.Option of under deck insulation of resin bonded glass wool / mineral wool.

- Application: Factory Buildings, Warehouses, InstitutionalBuildings etc

Install ZAP 167 standing seam roofing system:

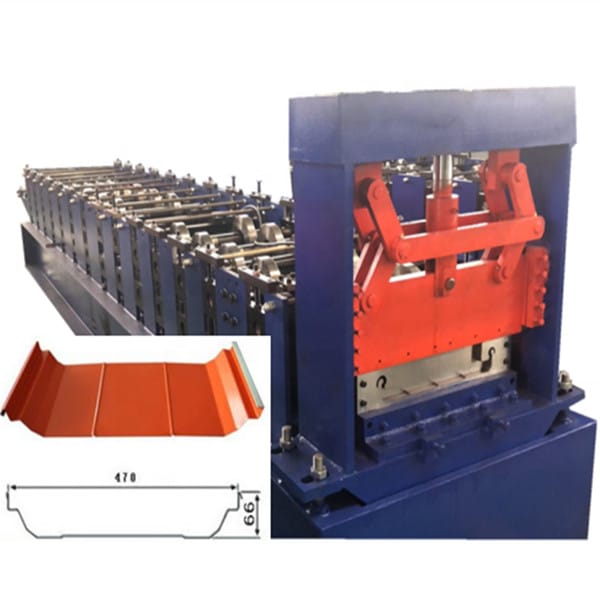

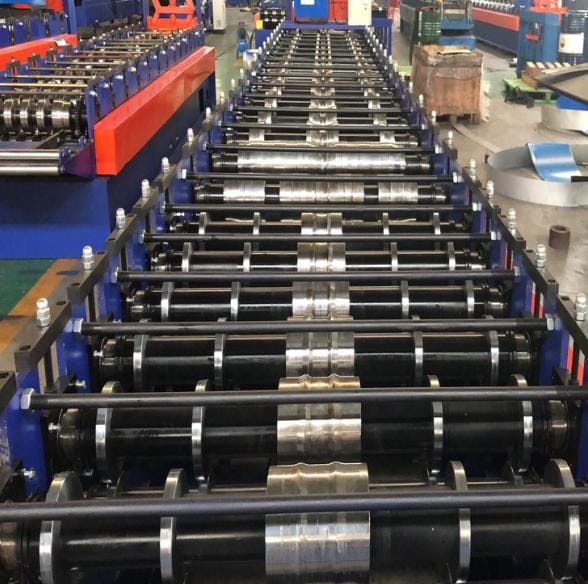

ZAP 167 standing seam roofing system rolling forming machine design:

More details of ZAP 167 standing seam roofing system rolling forming machine:

|  |

| |

| Here are some basic parameter of machine for your reference: | ||

| Production process Uncoiling→ Feeding material into machine→Roll forming→Measuring length→ Step formed→ Auto cutting→Products receiving | ||

| Coil feeding part Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate broad.The width is adjustable with handrail. And you also can use it as the cut to length machine. And for your machine, we will add two leveling rollers, the first before input coil and the other after input coil. | ||

| Forming device Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working Feature: Ensure stability, precision and lifetime. | ||

| No. | Main parameter | |

| 1 | Length of the main part | 7500 х 1650 х 1450 mm |

| 2 | Weight of main part | 6 Ton |

| 3 | Voltage | 380 V/ 50 HZ 3 Phase (as customer’s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | 350 H steel welded |

| 6 | Frame thickness | 18 mm thicker to be very strong |

| 7 | Drive mode | Chain of 1.25mm |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ 70 mm |

| 11 | Number of rollers | 16 rollers |

| 14 | Main power | 5.5kw |

For the Standing seam roofing system rolling forming machine ZAP 167 rolling forming machine, if you want to know more information, please contact us at any time.